Case Study – Large Walk-in Wine Cellar by Red Cedar

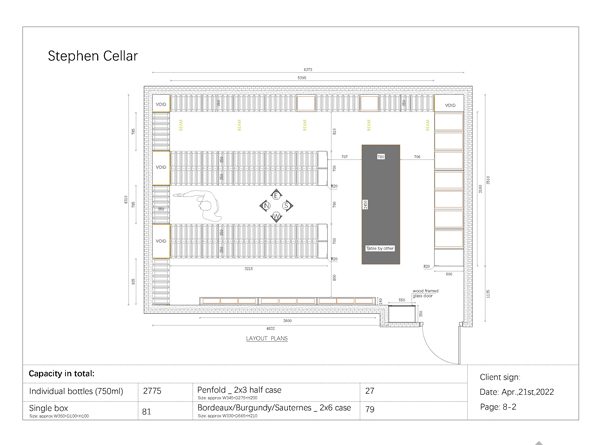

In November last year, Stephen from Melbourne consulted with us about the wine racking design for his large walk-in wine cellar. It’s a quite big one, room size 6.3 meters by 4.3 meters (about 20.5ft by 14ft), ceiling height around 2.4 meters(8ft).

As Stephen’s preference, the wood to make these racking is red cedar. This is a fragrant and antiseptic wood and is often used to make wine racks and cabinets.

At the design stage, we had two main problems.

- The capacity

Stephen collects over 2500 bottles of various wine and over 100 boxed wine, which means the new wine racking design should provide enough space for individual bottles as well as the boxed ones.

In our previous article about capacity mentioned, to estimate how much wine racking we need, we can calculate it by referring to 50 bottles per square meter. Stephen owns over 3000 bottles (individual & boxed), which means in this large walk-in wine cellar, there should be over 60 square meters of racking. If we put the racking all around the wall, there are only about 46 square meters, so we need to create more storage space in the center.

After several discussions with Stephen, the final solution is to add two groups of wine racking as peninsulas against the north wall and put full-height cabinets for wine boxes on the south wall.

Total wine capacity is up to 2700+ individual bottles, 75 boxes of dozen wines, 30 boxes of haft-dozen wines, and 80 boxes of a single wine. This capacity has about a 15% surplus for Stephen’s future collections.

- The insulation and beams

The large walk-in cellar is in the basement of Stephen’s house. And we should lay insulation on walls and ceiling. Different from the common rooms, there are 5 big steel beams on the ceiling, going through the cellar. We could not measure the room sizes and the locations of beams until the insulation was finished. To use these spaces and have more capacity, we design wine racking between beams. The gaps between rackings and beams are filled up by fillers.

After the wine racking design was confirmed, and during the production stage, we start to arrange the oversea shipping for these racking. In our previous cases, we pack the racking on the pallets and load them into containers. This is a simple way of loading and unloading. Pallet-packing will waste more space than other packing way. In this case, Stephen’s cellar is quite large that, if we go with pallet-packing, one 20ft container is not enough to load all the pallets; but one 40ft container is too big for them. Another way is to pack all the wine rackings into cartons one by one. So we do the pre-planning about how to load the cartons into a 20ft container. The estimation shows that one 20ft container is enough for all cartons for Stephen, so finally, we decided to do carton-packing.

At the end of this June, we successfully load all the cartons into the container. Slightly different from the estimation, the container is almost filled up. After 30 days shipping, this container will arrive at Melbourne Port, and several days after that, all the wine rackings will be assembled to their appointed locations. We will update the site photos of this large wine cellar later.

If you are looking for a supplier of wine cellar solutions, welcome to contact us for more information.